- Home

- Agencies

- Department of Agriculture

- Department of Housing and Urban Development

- General Services Administration

- Department of Commerce

- Department of the Interior

- National Aeronautics and Space Administration

- Department of Defense

- Department of Justice

- National Science Foundation

- Department of Education

- Department of Labor

- Office of Personnel Management

- Department of Energy

- Department of State

- Small Business Administration

- Environmental Protection Agency

- Department of Transportation

- Social Security Administration

- Department of Health and Human Services

- Department of the Treasury

- U.S. Agency for International Development

- Department of Homeland Security

- Department of Veterans Affairs

- Goals

- Initiatives

- Programs

Miners in U.S. Safer, Healthier Than Ever

What is the Issue?

In 2009, about half of the Department of Labor’s (DOL) Mine Safety and Health Administration (MSHA) inspectors had two years or less of inspection experience. Mine operator violations and penalties skyrocketed and the number of contested cases peaked at approximately 89,000 citations in January 2011. In April 2010, the Upper Big Branch (UBB) Mine exploded, claiming the lives of 29 miners. This was the worst mine accident in 40 years.

What was the Intervention?

In response, MSHA launched an accident investigation and internal review to understand what happened at UBB. MSHA targeted problem mines through the impact inspection program (additional unannounced inspections) and the Pattern of Violations (POV) law, under which MSHA can close dangerous areas of a mine with a history of chronic violations until Significant and Substantial (S&S) violations are remedied. MSHA also increased enforcement of rules for mine ventilation and coal dust control to prevent mine explosions. Other procedures strengthened protection of miners’ rights and policies prohibiting advance notice of MSHA inspections.

To improve enforcement effectiveness, MSHA completely overhauled its inspection manuals, created a centralized agency policy development and review process, and retrained all enforcement staff. MSHA also used a strategic approach to rulemaking; for example, one rule lowered miners’ exposure to unhealthy coal mine dust and increased sampling, and another (proximity detection) was enacted to protect miners from being crushed by the huge continuous mining machines in underground coal mines.

How was Performance Management Useful?

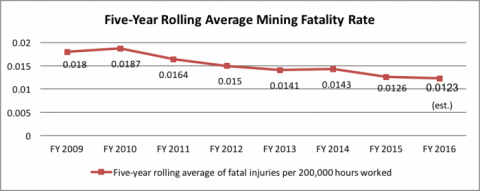

The Mine Act requires MSHA to inspect surface mines at least twice a year and underground mines at least four times a year; this covers over 13,000 mines that employ about 350,000 miners. MSHA maintains a wealth of data on all active mines in the U.S. and uses the data to aggressively enforce and improve mine safety and health standards. Since 2010, DOL has had an Agency Priority Goal (APG) for mine safety, measured by the fatal injuries per 200,000 hours worked (see chart below). MSHA uses many other measures to implement and monitor strategies for reducing the fatality rate APG and the all-injury rate and includes some of them in quarterly Operating Plan reviews with the Deputy Secretary.

What was the Impact?

In addition to the APG trend depicted in the graph below, MSHA achieved the following results from its major initiatives over the last seven years:

- A review of the mines that received impact inspections since April 2010 shows that overall compliance is improving at these mines. As of June 30, 2016, violations per inspection hour at these mines were down 22 percent; significant and substantial (S&S) violation rates decreased 33 percent; and rates of Section 104(d) violations for operators’ unwarrantable failure to comply with mandatory health and safety standards decreased 63 percent. The total lost time injury rate decreased two percent compared to the 12 months prior to each mine’s first impact inspection.

- As of June 30, 2016, the total violation rate for POV mines was down 43 percent; the S&S violation rate was down 67 percent; and the rate of unwarrantable failure violations decreased by 85 percent. The lost time injury rate dropped by 56 percent compared to the 12 months prior to each mine’s evaluation period.

- To reduce the contested case backlog, MSHA obtained supplemental funding to create a pre-assessment conference process that could resolve violations without litigation. This process helped reduce the total number of contested cases in inventory by 83 percent (from 89,000 at the end of FY 2010 to 15,000 at the end of FY 2016).

- During the first twelve months of the new respirable dust rule, the yearly average exposure for the dustiest occupations dropped to the lowest levels ever at 0.65 milligrams per cubic meter of air (mg/m3).